303 Stainless Steels – ASTM F899 Standard Austenitic Material

What is 303 Stainless Steel?

303 stainless steel is known as austenitic because of its non-magnetic or non-martensitic behavior, unlike 420A stainless steel which has higher Carbon content This has higher chromium up-to 19%. The uniqueness of this type is its machinability due to sulfur content.

303 stainless steel grade is distinct due to its exclusive mechanical & physical properties. It has got unique nature of machinability. Its corrosion resistance is not as strong as in other grades of the family. Moreover, it has worthy resistance to oxidation when irregularly exposed to the temperature up to 760-degree centigrade. Weldability is not superb due to sulfur content, however, there are some filler materials that can weld it.

Dimensional Characteristics of 303 Stainless steel: The applicable thickness in millimeters for this 303 Stainless steel ranges from 0.25 to 4 whereas the width in millimeters is from 600 to 1200. Moreover

the Internal diameter of the pipe form in inches is from 3.25 to 7.

Available Forms in Market

Following are the available forms of 303 Stainless steel:

- Sheets

- Round Bars & Pipes

- Machined Parts

- Coils

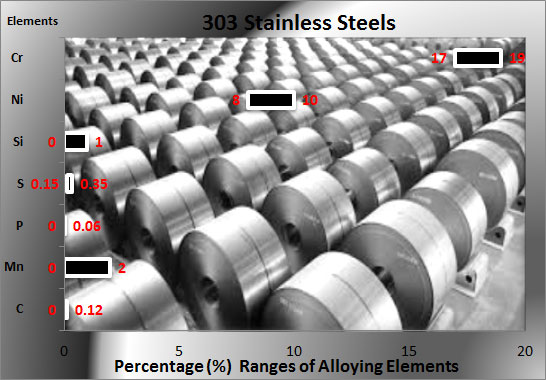

The Chemical Composition of 303 Stainless Steel

Chemical alloying compositions are explicated below

- Maximum percentage of Carbon as defined in the standard is 0.12

- Maximum percentage of Manganese (Mn) as defined in the standard is 2

303 Stainless Steel Composition

- Maximum percentage of Phosphorus as defined in the standard is 0.06

- Maximum percentage of Sulfur as defined in the standard is 0.35 where as minimum percentage is 0.15%

- Maximum percentage of Silicon as defined in the standard is 1

- Maximum percentage of Nickel as defined in the standard is 10 whereas minimum is 8%

- Maximum percentage of Chromium as defined in the standard is 19 whereas Minimum percentage of Chromium as defined in the standard is 17

Recommendation: 303 type is not recommended for environments having chlorides or environment over fifty degree centigrade, because it develops pitting and crevice corrosion. Therefore it should not be applied in marine environments.

Mechanical Properties of 303 Stainless steel

Mechanical properties are as under

- Tensile strength is from 500 to 750 Mpa in some technical sources.

- Hardness in HB as specified in technical sources is from 48 to 230.

- Yield strength (Proof stress) is from 190 Mpa in some technical sources.

- Elongation is 35% in the standard.

Equivalent Materials of 303 Stainless steel

The equivalent materials for 303 Stainless steel specified in other recognized standards are listed as under

- In JIS standard, the equivalent material is referred to as SUS 303 type steel.

- In DIN standard, the equivalent material is referred as 1.4305 type steel.

- In UNS standard, the equivalent material is referred to as S30300 type steel.

Industrial Applications of 303 Stainless steel

These are used in a variety of industrial applications including

- Chisels, curettes, & knives

- Specula, Probes & suction tubes

- Nut, bolts, screws and bushings

- electrical switch-gear parts

- Mechanical Shafts

Note: These values are indicative and for information purpose only. Some of the given information can be outdated. There are also minor possibilities for inaccuracies in the text due to human error. For inaccuracies & outdated text, you can complaint us.