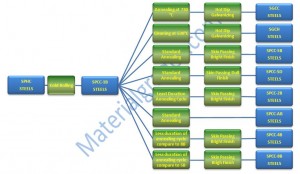

Commercial Quality Mild Steel Grades Relationship Matrix

The figure 1 illustrated below in the article shows that how different mild steel grades are linked together with different processes, material grades are represented in blue boxes where as industrial processes are presented in green boxes. The figure is explained by a supporting article below.

Once the billets for commercial quality hot rolled SPHC steel is prepared with the due chemical composition in the melt shop, then it is rolled to form hot rolled slabs, the slabs are further re-rolled above the re-crystallization temperature to form hot rolled coils with material grade of SPHC steels. The hardness of SPHC steels is about 45-60 HRB.

Learn about SPHC steels.

SPHC steels served as a raw material for many material grades as illustrated in the figure. Cold rolling operation can prepare SPCC-1B steels.

After following cold rolling operation on SPHC coils in a rolling mill, SPCC-1B can be prepared. Depends on the reduction percentage the material is hardened. Normally when SPHC steels are reduced to 85-90 percent it gives SPCC-1B steels. The hardness of SPCC-1B steels is 85 HRB.

The basic primary operation over SPHC steels has been performed and the cold roll steel has been prepared, this cold rolled steel with designation of SPCC-1B can be further processed to prepare several material grades:

- SGCC Steels (Commercial Quality Soft Galvanized Steel)

- SGCH Steels (Commercial Quality Hard Galvanized Steel)

- SPCC-SB Steels (Commercial Quality Standard Temper Bright Finish Steel)

- SPCC-SD Steels (Commercial Quality Standard Temper Dull Finish Steel)

- SPCC-2B Steels (Commercial Quality Half Hard Bright Finish Steel)

- SPCC-AB Steels (Commercial Quality Annealed Bright Finish Steel)

- SPCC-4B Steels (Commercial Quality Quarter Hard Bright Finish Steel)

- SPCC-8B Steels (Commercial Quality One Eighth Hard Bright Finish Steel)

Preparation of SGCC Steels

SGCC steels are prepared when SPCC-1B steels are galvanized at hot dip galvanization lines, the temperature of the furnace is kept high about 730 °C so as to give Commercial Quality Soft Galvanized Steel. Hardness is less than or equal to 55 HRB).

Read more about this type of steels here: SGCC Steels.

Preparation of SGCH Steels

SPCC-1B steels are galvanized in the same manner in hot dip galvanization lines but the temperature of annealing is kept a 530°C to give SPCH steel which are relatively hard. Hardness is greater or equal to 85 HRB)

Preparation of SPCC-SB or SPCC-SD Steels

Now as for the preparation of SPCC-SB Steels, SPCC-1B steels are first annealed in a bell type annealing furnace. The annealed material is called as SPCC-AB Steels. The hardness of SPCC-AB steels is about 57 HRB max. This annealed material is not a finished cold roll steel and thus it is skin-passed with one and half percent reduction to give SPCC-SB steels. The work rolls being used to produce SPCC-SB steels are bright finish. The hardness of SPCC-SB steels is no more than 65 HRB. Similar with case of SPCC-SD steels, the only difference is that the work rolls are shot blasted to give a dull finish to steel.

Read more about SPCC-SB & SD Steel.

Preparation of SPCC-2B, SPCC-4B & SPCC-8D Steels

The procedure of making SPCC-2B, SPCC-4B & SPCC-8D steels is in general similar to that of SPCC-SB steels, the only difference is about the ramp heating time in the annealing furnace and slight variation in chemical composition of steel, although it lies in the same range of chemical composition of SPCC. When chemical composition SPCC-8D to SPCC-4B to SPCC-2B is considered, we observe an increasing trend of carbon in it. The change is about 0.01-0.02 % and but under the maximum limit i.e. 0.15 %. For example in SPCC-8D steels carbon percentage is about 0.09 %, in SPCC-4B it is 0.11 % and in SPCC-8D it is 0.13 %. Similarly the annealing ramp heating time also decreases from SPCC-8D to SPCC-4B to SPCC-2B. The hardness of these steels is as follows:

SPCC-8D Steel – Hardness is about 52 to 73.2 HRB.

SPCC-4B Steel – Hardness is about 65 to 78.7 HRB.

SPCC-2B Steel – Hardness is about 73.2 to 88.8 HRB.

What does SPCC S D N INDICATES AS PER JIS 3141

In “SPCC SD”, ‘S’ is the standard quality cold rolled and ‘D’ is the dull surface finish.

This material are more commonly found and available in the market and require secondary process like plating done on the surface of the parts as bare material tends to rust easily upon purchase.

What is the different between mild steel and SPCC. Especially on the magnetic characteristic.

It is very helpful information. Thank you. I have a few questions, if you dont mind me asking. What about steel with anti-fingerprinted and galvalume steel ? are they also from the same branch as SPHC ? thanks much.

It is not necessary. But we can make galvalume by SPHC.