ASTM F899 410 Martensitic Wrought Stainless Steels

What is 410 Stainless Steels? 410 is the primary martensitic stainless which reflects great mechanical properties after heat treatment. This type of steel has great impact strength, corrosion and scaling resistance.

Dimensional Characteristics of 410 Stainless Steels: The applicable thickness in millimeters for this 410 Stainless Steels ranges from 0.25 to 4 whereas the width in millimeters is from 600 to 1200. Moreover outer diameter of pipe in inches ranges from 0.5 to 8. In the case of rod the diameter in inches is from 1 to 8.

Available Forms in Market: Following are the available forms of 410 Stainless Steels:

- Sheets

- Round Bar

- Forgings

- Pipes

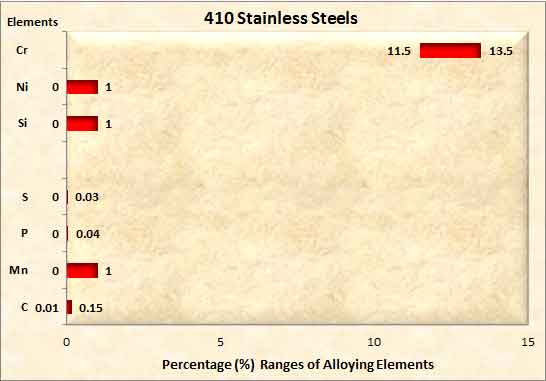

The Chemical Composition of 410 Stainless Steels: Chemical alloying compositions are explicated below

- Maximum percentage of Carbon as defined in the standard is 0.15 whereas Minimum percentage of Carbon as defined in the standard is 0.01

- Maximum percentage of Manganese as defined in the standard is 1

- Maximum percentage of Phosphorus as defined in the standard is 0.04

- Maximum percentage of Sulphur as defined in the standard is 0.03

- Maximum percentage of Silicon as defined in the standard is 1

- Maximum percentage of Nickel as defined in the standard is 1

- Maximum percentage of Chromium as defined in the standard is 13.5 whereas Minimum percentage of Chromium as defined in the standard is 11.5

Crux: This material specification is best for hardening, however it is also good for machining in soft annealed conditions. Heat treatment plays a vital role in its mechanical properties.

Mechanical Properties of 410 Stainless Steels: Mechanical properties are as under

- Hardness in HRC as specified in the standard is from 24 to 43.

- Tensile strength is not defined in the standard.

- Yield strength is not defined in the standard.

- Elongation is not defined in the standard.

Equivalent Materials of 410 Stainless Steels: The equivalent materials for 410 Stainless Steels specified in other recognized standards are listed as under

- In JIS standard, the equivalent material is referred as 410 type steel.

- In DIN standard, the equivalent material is referred as 1.4006 type steel.

- In ISO standard, the equivalent material is referred as 410 type steel.

Industrial Applications of 410 Stainless Steels: These are used in variety of industrial applications including

- Surgical Instruments

- Kitchen utensils

- Fasteners

- Gas turbine blades

- Valve components

Note: These values are indicative and for information purpose only. Some of the given information can be outdated. There are also minor possibilities for inaccuracies in the text due to human error. For inaccuracies & outdated text you can e-mail & inform the Content Manager at materialgrades@yahoo.com