ASTM A283 Intermediate Strength Hot Rolled Grade A Steel

What is Grade A Steels? Grade A steel is a low & intermediate tensile strength hot Rolled steel in the form of plates for general Intermediate Strength applications. Grade A is a material grade and designation defined in ASTM A283 standard. ASTM A283 is an American material standard for hot Rolled steel plates for general intermediate strength usage.

Dimensional Characteristics of Grade A Steels: The applicable thickness for this Grade A material as defined in the ASTM A283 starts from 6 mm to 50 mm. The width is normally from 600 mm to 2000 mm.

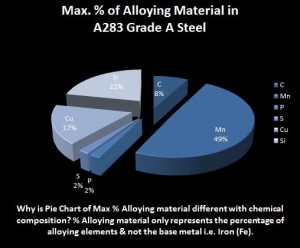

The Chemical Composition of Grade A Steels: ASTM A283 defines the chemical composition of Grade A steels as under:

Maximum percentage of Carbon (C) is 0.14

Maximum percentage of Silicon (Si) is 0.4

Maximum percentage of Manganese (Mn) is 0.9

Maximum percentage of Phosphorous (P) is 0.035

Maximum percentage of Sulphur (S) is 0.040

Minimum percentage of Copper (Cu) is 0.20

Remaining is iron (Fe) percentage and with few negligible impurities.

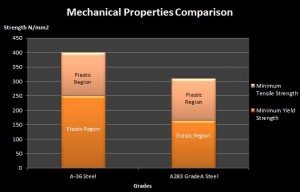

Mechanical Properties of Grade A Steel: The tensile strength of the Grade A Steels is expressed in Newton per millimeters and it must be at-least 310 N/mm2 (MPa). The yield strength is minimum 165 N/mm2 (MPa). The minimum percentage ranges for elongation is 30%.

Grade A steel comparison with this grade of A36 material will show how it differs with higher strength steel in chemical composition & mechanical properties.

Hi sir

I would like to ask you about the material carbon steel A283 GrA why we can not be used this material in construction of oil storage tank ,using butt joints weld.

Thank-you for your attention

Best regards

Mr. Akram,

Thank you for your question.

Since the minimum tensile strength as defined by the American standard of this material ASTM A283 is 310 N/mm2, so if we consider this type steel for oil storage tanks that is of usually intermediate strength and is not a structural quality strength. But for oil storage tanks high strength quality steel is required which can cope up with hydro-statically induced pressure of oil.

Moreover for manufacturing oil storage tanks, standards of API are used which clearly explicate high strength steel such as API 650 standard. The design stresses for oil storage tanks are usually 123 N/mm2 as per the API 650 standard and the minimum tensile strength required including the safety factor is 380 N/mm2. Therefore ASTM A283 doesn’t meet this requirement.