440C Martensitic Stainless Steels in ASTM F899 Standard

What are 440C Stainless Steels? 440C stainless steel grade is high chromium & carbon magnetic stainless steel. The material structure is martensitic. It has high Ultimate tensile strength, reasonable corrosion resistance, and robust hardness and wear protection. After heat treatment processes Stainless type 440C is proficient of accomplishing uppermost UTS, resistance to permanent indentation and wear protection among many other stainless alloys. These all discussed qualities are because of very high carbon content. These robust qualities make stainless grade 440C mainly well-matched to uses in valve components and ball bearings. The Carbon Content of 440C stainless steel is more than 420A stainless steel thus this 440C can achieve higher hardness after treatments.

Dimensional Characteristics of 440C Stainless Steels: The applicable thickness in millimeters for this 440C Stainless Steels ranges from 0.25 to 4 whereas the width in millimeters is from 600 to 1200. Moreover the diameter of the round bars is from .3125 to 6 inches.

Available Forms in Market: Following are the available forms of 440C Stainless Steels:

- Sheets

- Round Bars & Pipes

- Plates

- Coils

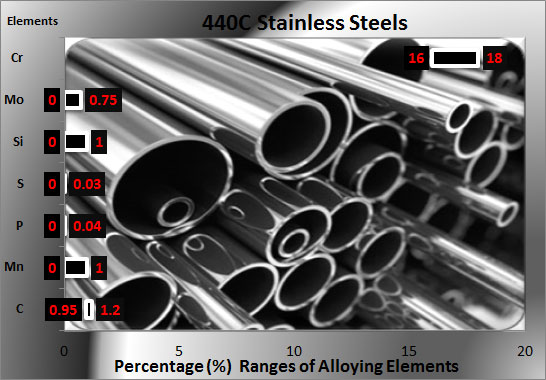

The Chemical Composition of 440C Stainless Steels: Chemical alloying compositions are explicated below

- Maximum percentage of Carbon as defined in the standard is 1.2 whereas Minimum percentage of Carbon as defined in the standard is 0.95

- Maximum percentage of Manganese as defined in the standard is 1

- Maximum percentage of Phosphorus as defined in the standard is 0.04

- Maximum percentage of Sulphur as defined in the standard is 0.03

- Maximum percentage of Silicon as defined in the standard is 1

- Maximum percentage of Nickel as defined in the standard is 0.75

- Maximum percentage of Chromium as defined in the standard is 18 whereas Minimum percentage of Chromium as defined in the standard is 16

Crux: 440C stainless steel grade is known for its good corrosion resistance in mild inland and manufacturing surroundings as well as with fresh water, organic constituents, and in numerous petroleum lines. Type 440C stainless steel is not easily fused & welded since it can be simply hardened at room temperatures therefore becoming brittle. In order to weld this grade, it should be warmed to 260 degree centigrade equivalent around 500 Fahrenheit. Moreover after the weld is made it should be heat treated again at 760 degree centigrade equivalent around 1400 Fahrenheit for about six hours. After which it should be gradually cooled in the heater to avoid cracking.

Mechanical Properties of 440C Stainless Steels: Mechanical properties are as under

- Hardness in HRC as specified in technical sources is from 24 to 58.

- Tensile strength is around 785 Mpa in some sources.

- Yield strength is around 420 Mpa in some sources.

- Elongation is 35% in 50mm as mentioned in a source.

Equivalent Materials of 440C Stainless Steels: The equivalent materials for 440C Stainless Steels specified in other recognized standards are listed as under

- In JIS standard, the equivalent material is referred as SUS 440C type steel.

- In DIN standard, the equivalent material is referred as 1.4125 type steel.

- In UNS standard, the equivalent material is referred as S44000 type steel.

Industrial Applications of 440C Stainless Steels: These are used in variety of industrial applications including

- Pump components & Valve Parts

- Gauge Blocks for calibration

- Molds and Dies

- Metrological & Surgical Instruments

- Knives and cutleries

Note: These values are indicative and for information purpose only. Some of the given information can be outdated. There are also minor possibilities for inaccuracies in the text due to human error. For inaccuracies & outdated text you can e-mail & inform the Content Manager at materialgrades@yahoo.com