JIS G3112 Reinforcement bar SR24 Billet Steel

What is SR24 Steels? SR24 steel is a structural billet steel for structural applications. SR24 is a material grade and designation defined in JIS G3112 standard. JIS G3112 is an international material standard for reinforcement bar billet steel for strengthening application.

Dimensional Characteristics of SR24 Steels: The applicable diameter for this SR24 material as defined in the JIS G3112 starts from 6 mm to 34 mm. The length is usually around 10 to 12 meters.

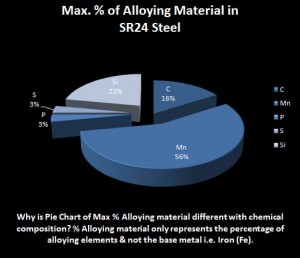

The Chemical Composition of SR24 Steels: JIS G3112 defines the chemical composition of SR24 steels as under:

Maximum percentage of Carbon (C) is 0.25.

Maximum percentage of Manganese (Mn) is 0.9.

Maximum percentage of Phosphorous (P) is 0.050 percent.

Maximum percentage of Sulphur (S) is 0.050 percent.

Maximum percentage of Silicon (Si) is 0.350 percent.

Remaining is iron (Fe) percentage and with few negligible impurities.

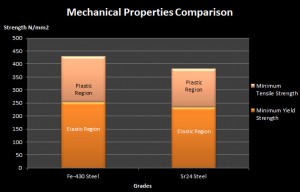

Mechanical Properties of SR24 Steels: The tensile strength of the SR24 Steels is expressed in Newton per millimeters and it must be at-least 382 N/mm2 (MPa). The yield strength is minimum 235 N/mm2 (MPa). The minimum percentage ranges for elongation is 24% thicknesses.

SR24 steel reinforcement bar billets are used for re-enforcement work for town house, office buildings, bridge, concrete road, agricultural equipment and in other industrial applications. Comparison with Fe-310 Steels Billets will show how it differs with structural billet steel.

I want to know the min percentage of chemical position